Testing & Calibration

Periodic Testing & Compliance

PUWER Inspections

LOLER Inspections and Certification

WAH Inspections and Certification

Bespoke Periodic Inspections service

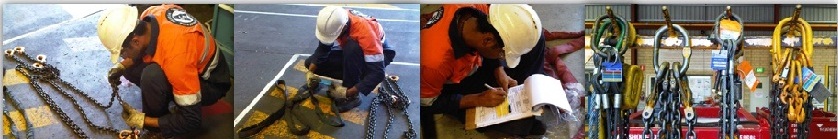

Lifting Operations and Lifting Equipment Regulations 1998 (LOLER)

We carry out the inspection of lifting equipment. Equipment covered by these regulations include:

Passenger & Goods Lifts

Fork Lift Trucks

Hoists

Excavators & Earth Moving Equipment

Cranes, Mobile and Fixed

Window Cleaning Rigs

Lifting equipment includes any equipment used at work for lifting or lowering loads, including attachments used for anchoring, fixing or supporting.

The regulations cover a wide range of equipment including, cranes, forklift trucks, lifts, hoists, mobile elevating work platforms and vehicle inspection platform hoists.

The definition also includes lifting accessories such as chains, slings, eyebolts etc.

Lifting Accessories List

Block/Brick/Kerb Grab

Cam Clutch Lifting Eye

Cargo Net

Chain Sling

Climbing Rope

Concrete Skip

Crane Forks

Crane Scale/Load cell

Doughty Coupler

Endless Polyester Sling

Eye Bolt

Fibre Rope Sling

Gin Wheel

Girder Clamp

Grab

Hook

Hull Lifting Attachment

Lifting Beam

Lifting Cleat

Lifting Frame

Lifting Tong

Magnet

Manhole lifting Pin

Personnel Lifting Sling

Plate Clamp

Rigging Screws

Ring Clutch Lifting Eye

Safety Harness

Safety Lanyard

Shackle

Snatch Block

Spreader Beam

Storage Basket

Swivel

Web/Belt Sling

Wire Rope Sling

Consultancy and Advisory

The inspection is specifically to identify defects which are or may become a danger to persons so that they can be rectified.

Ideally these should be rectified as soon as possible, however, some are more important than others and so defects are categorised according to the severity of defect.

wWhen they need to be rectified and whether they must be reported to the enforcing authority (In certain cases this is a legal requirement and is required whether the defect is rectified at the time or not.).

Inspection Services

When we provide ‘inspection services’ and our Engineer Surveyor (also known as the ‘Competent Person’) would make an appointment, confirm availability of the equipment and on arrival provide identification and complete any formal health and safety site requirements.

A site risk assessment would be carried out on the equipment, ensuring firstly that it is safe to examine and, secondly, identifying the safety critical parts, considering the type and complexity, risks involved, use, age, condition, servicing state, repairs carried out, environment and other aspects relevant to the continued safety of the equipment.

This will determine the scope of inspection, which would include a thorough visual examination of accessible parts of the item, focused on those safety critical components and their potential for failure, mechanical or electrical safety devices designed to protect persons and functional testing as appropriate.

Where Engineer Surveyors cannot be assured, for example hidden load bearing components, they may call for additional supplementary tests. These would be more intrusive and normally carried out by the equipment servicing company or specialist testing organisation eg NDT.

Click on this text to edit it.

Click on this text to edAny lift inspection should never be overlooked, as always HSEpro inspection services are more than happy to assist you.

Alongside our expert lift maintenance and emergency call out services, we also provide our residential and commercial customers with testing and inspection options throughout London, Essex, Suffolk,Norfolk and all the Home Counties.t it.